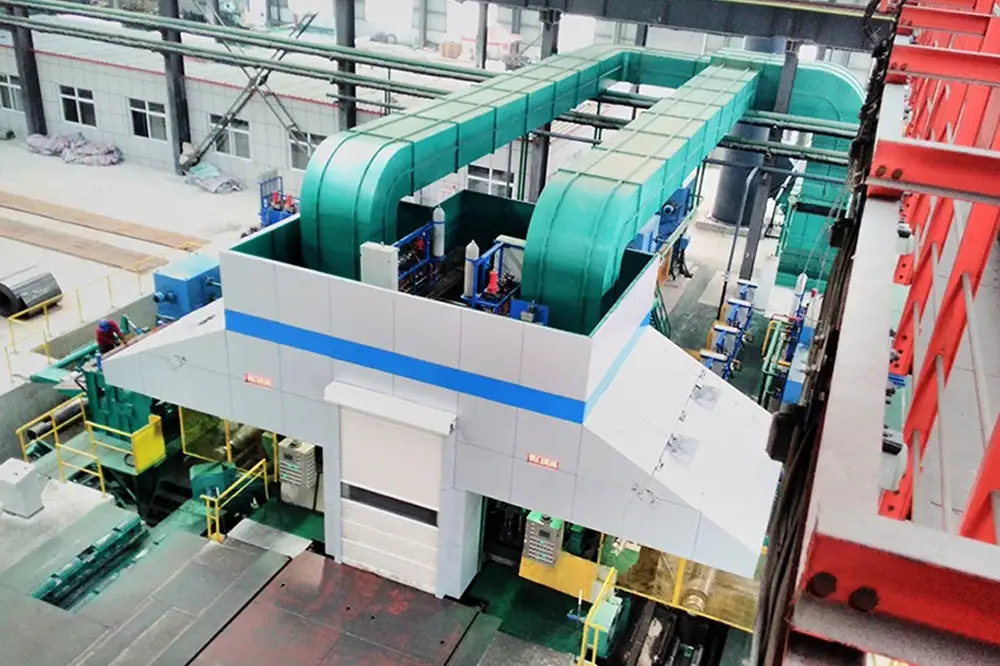

Hito Engineering has established itself as a leader in advanced steel processing solutions, especially with its innovative continuous pickling line technology. This technology plays a vital role in the production of high-quality steel sheets by removing surface impurities that form during the hot rolling process. The continuous nature of these lines allows for constant and efficient processing, significantly reducing downtime and boosting overall productivity. What sets Hito Engineering apart is their ability to integrate cutting-edge automation, energy-efficient systems, and environmentally friendly practices into their pickling lines, ensuring their clients receive maximum benefits in terms of quality, safety, and operational efficiency.

Enhanced Surface Quality and Finish

One of the primary benefits of Hito Engineering’s pickling line technology is the outstanding surface quality it produces. The process effectively removes rust, scale, and oxide layers, leaving behind a smooth, clean surface ready for further processing such as coating or galvanizing. The precision control systems implemented in their lines ensure uniform removal of impurities, which minimizes surface defects and results in a superior finish. This high-quality surface not only enhances the aesthetic appeal of the final product but also improves its corrosion resistance and overall durability, making it ideal for applications that demand strict quality standards.

Superior Process Automation and Control

Hito Engineering’s continuous pickling lines are renowned for their sophisticated automation systems that provide precise control over each phase of the process. Automated chemical dosing, real-time monitoring sensors, and digital control algorithms work together to optimize chemical consumption, reduce waste, and enhance safety. Automated process adjustments are made based on real-time data, ensuring consistency regardless of variations in incoming steel or environmental factors. This level of control helps eliminate human error, accelerates processing times, and ensures every batch meets the desired quality specifications, making the production process smoother and more predictable.

Operational Efficiency and Increased Throughput

One of the most significant advantages offered by Hito Engineering’s pickling line solutions is their ability to dramatically improve operational efficiency. The continuous, automated nature of these systems allows for higher throughput without compromising quality. By minimizing downtime for cleaning, maintenance, and setup, these lines enable steel producers to maximize their output. Faster processing times not only meet market demands more effectively but also lower the costs associated with labor and energy. The systems are designed to handle large volumes of steel continuously, making them ideal for high-capacity manufacturing plants seeking to boost their productivity and profit margins.

Environmental Sustainability and Eco-Friendly Operations

Hito Engineering places a strong emphasis on environmentally sustainable practices within their pickling solutions. Their systems incorporate features such as chemical recycling, waste treatment modules, and energy-efficient components, aiming to reduce the environmental footprint of steel processing. Advanced acid management techniques minimize chemical wastage, while effluent treatment facilities ensure waste is properly treated and disposed of, conforming to international environmental standards. These eco-friendly features not only help steel producers meet strict regulations but also promote corporate social responsibility by supporting sustainable manufacturing practices.

Cost Savings and Reduced Operational Expenses

Implementing Hito Engineering’s advanced pickling lines translates into notable cost savings for steel manufacturers. The high level of automation and process control reduces the need for manual interventions, decreasing labor costs and minimizing human errors. Optimized chemical consumption and energy efficiency lower operational expenses significantly. Furthermore, the improved surface quality reduces the need for additional finishing processes, thus saving on downstream costs. The durability and low maintenance requirements of their equipment also contribute to reduced long-term expenses, making their solutions economically advantageous for large-scale steel plants.

Future-Proofing Steel Manufacturing with Innovative Technologies

As the steel industry faces increasing pressure to adopt greener and smarter manufacturing practices, Hito Engineering continually innovates to stay ahead. Their current focus is on integrating digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics into their pickling systems. These innovations enable predictive maintenance, real-time process optimization, and enhanced quality assurance. Future developments aim at zero-discharge systems and further reduction in chemical use. By staying at the forefront of technological advancements, Hito Engineering ensures their solutions remain relevant and capable of supporting the evolving needs of the steel metallurgy sector, helping manufacturers future-proof their operations.

Conclusion: A New Standard in Steel Processing

Hito Engineering’s continuous pickling line technology exemplifies how innovation and precision engineering can significantly enhance steel manufacturing. The myriad benefits—including superior surface quality, operational efficiency, environmental sustainability, and cost savings—highlight why their solutions are widely regarded as industry benchmarks. With ongoing advancements in digital and eco-friendly technologies, Hito Engineering continues to set new standards in the field, empowering steel producers worldwide to achieve higher productivity, better product quality, and sustainable growth. Their commitment to excellence makes them a pivotal partner for the future of steel metallurgy.